In modern industry, leveraging cutting-edge technologies to enhance efficiency and reduce costs is essential.

For sectors such as food processing and chemical manufacturing, the integration of advanced monitoring and automation systems lead to significant improvements in productivity and sustainability.

This blog post explores the advantages of deploying sensors within industrial facilities to monitor energy consumption, machine settings, and production receipts. And it highlights the benefits of implementing SCADA or OPC systems to streamline these processes. Furthermore, we will delve into the transformative potential of AI automation to optimize production processes and reduce energy costs.

The Advantages of Sensor Deployment in Industrial Facilities

Monitoring Energy Consumption

The first step towards optimizing energy usage is understanding how and where energy is consumed within an industrial facility.

Deploying sensors to monitor energy consumption provides real-time data, enabling the identification of inefficiencies and energy-draining processes. This data is critical for implementing targeted energy-saving measures, reducing operational costs, and contributing to sustainability goals.

Optimizing Machine Settings

Sensors play a pivotal role in ensuring that machinery operates at peak efficiency. By continuously monitoring parameters such as temperature, pressure, and speed, sensors help maintain optimal machine settings. This not only extends the lifespan of equipment , but also ensures consistent product quality, minimizing waste and reducing downtime.

Enhancing Industrial Receipts

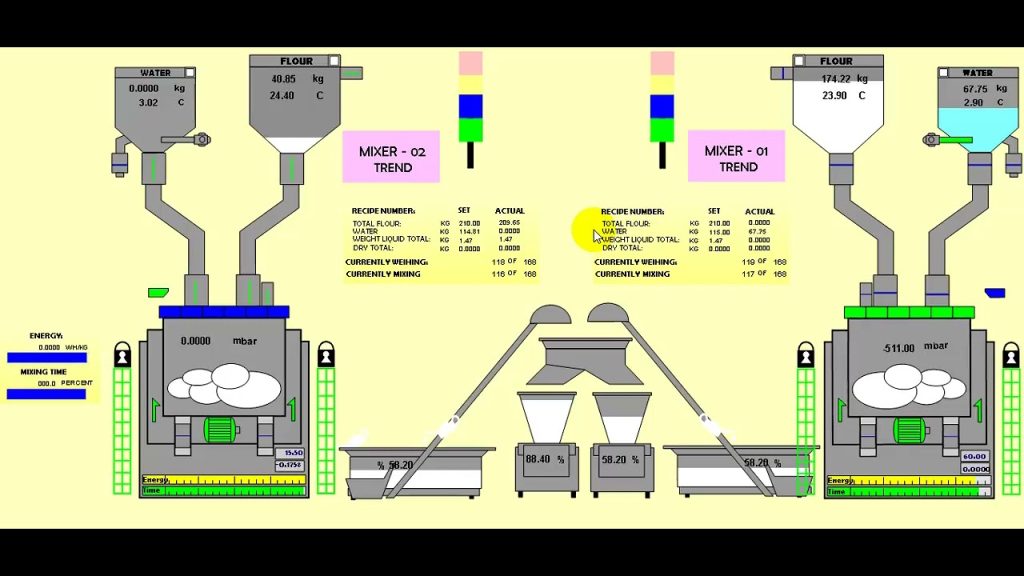

In industries like food processing and chemical manufacturing, precision is key. Sensors can accurately measure and control the quantities and timings of ingredients or chemicals, ensuring adherence to precise recipes or formulations. This level of control improves product consistency, reduces material waste, and enhances overall process efficiency.

Streamlining Operations with SCADA and OPC Systems

SCADA Systems

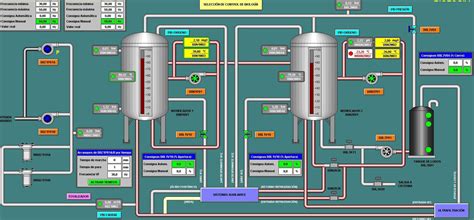

SCADA (Supervisory Control and Data Acquisition) systems offer a centralized platform for collecting, analyzing, and acting upon data from various sensors across an industrial facility. By integrating SCADA, operators gain a holistic view of all processes, enabling swift and informed decision-making. SCADA systems automate routine control tasks, reducing human error and increasing operational efficiency.

OPC-UA Systems

OPC (Open Platform Communications) systems facilitate seamless communication between different hardware and software components within the industrial environment. By standardizing data exchange protocols, OPC systems ensure interoperability between diverse devices and applications. This connectivity is essential for implementing sophisticated automation and control strategies, further enhancing process efficiency.

Leveraging Data Streams for Strategic Decision-Making

The true power of sensor deployment and SCADA or OPC integration lies in the ability to harness and analyze the resulting data streams. By converting raw data into actionable insights, manufacturers make strategic decisions that drive efficiency and profitability.

For instance, analyzing energy consumption patterns can reveal opportunities for targeted investments in energy-saving technologies. Similarly, performance data from machinery inform preventative maintenance schedules, reducing the risk of costly breakdowns and ensuring uninterrupted production.

Automating Repetitive Tasks with AI

One of the most exciting developments in industrial automation is the application of artificial intelligence (AI) to automate repetitive tasks traditionally performed by humans.

AI technology deploys the ability to process and use information to make predictions about the way that the world might unfold around you. Once a prediction is made, you can use it to make an intervention … or the AI system executes it autonomously, to adjust the course of some environment.

BeChained offers to industrial manufacturers an AI solution that learns how production processes work. It first gathers information from smart-meters, MES (machine’s settings) and production batches and circles back to MES the changes to deliver substantial efficiency in those industrial process.

BeChained experienced a 20-25% improvements in non-critical processes, i.e. water management, air compressors, exhaust or dust extraction, grinding and air conditioning. Or in critical ones, i.e. thermal treatments in metal making or painting in automotive or white goods.

BeChained: Transforming Industrial Efficiency

BeChained delivers continuous reduction energy costs and carbon offset spending by making production processes more energy-efficient by 20-25%. Its AI solution continuously learns from real-time data streams, including energy consumption, machine settings, and production schedules.

By training its model on this dynamic data, BeChained identifies optimal machine settings and crafts precise instructions for direct implementation, via SCADA or OPC-UA systems.

This level of automation transforms a factory into an autonomous system, akin to the robotization seen in autonomous vehicles like those developed by Waymo.

By automating routine and repetitive tasks, BeChained frees human workers to focus on more creative and qualitative aspects of production, such as improving recipes or exploring alternative ingredients.

Meanwhile, this automatization guarantees more productivity and reduce the downtimes in production lines, while delivering efficiency in costs and GHG emissions.

Conclusion

The deployment of sensors, coupled with the integration of SCADA or OPC systems and the automation capabilities of AI, marks a new era in industrial efficiency.

Solutions like BeChained exemplify how these technologies can reduce energy costs, improve operational efficiency, and foster a more sustainable industrial landscape. By embracing these advancements, industries can enhance their competitive edge, optimize resource use, and contribute to a more sustainable future.

Incorporating these technologies not only drives immediate operational benefits, but also positions companies to thrive in an increasingly data-driven and automated industrial environment. BeChained experienced a Return on Investment in less than 1 year, where for every $1 invested in its solutions, clients save $4.