Challenge

Our client, a leader in Steel high pressure tube production wanted to reduce electricity consumption for electric processes along a large Rolling mill.

Solution

We analysed either one-year history of consumption data and influence variables (i.e. energy consumption, machine’s settings and batch scheduling) and real-time information.

After a adapting the formulated model to the specific device, enriched with descriptive analytics of the available data, BeChained established a electricity consumption model based on RL algorithms, identifying and highlighting the most important influential variables.

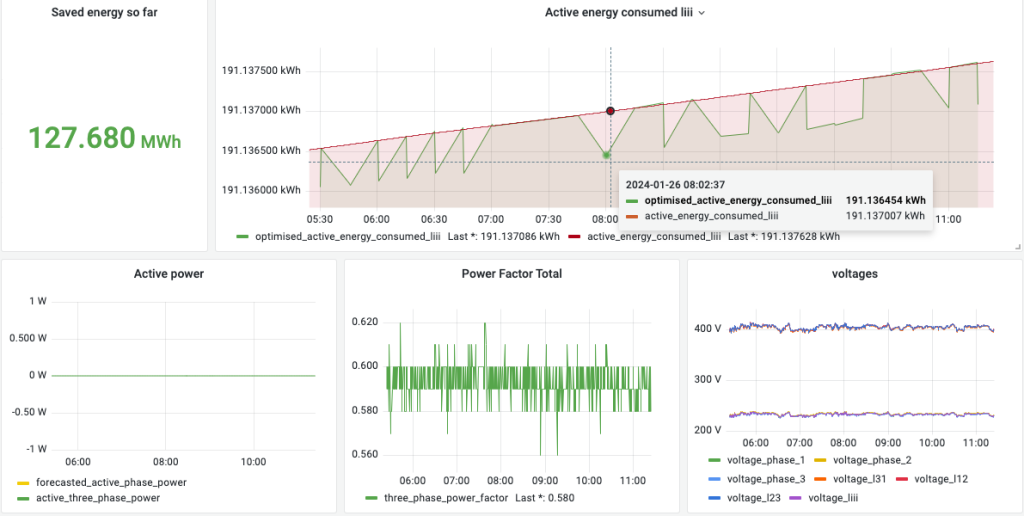

Hence, the baseline calculated is then compared every quarti-hour with the actual consumption. This makes possible to quickly detect any abnormal consumption, and correcting the set-points to keep the overall consumption at the minimum level.

It works with water pumps, air compressor, exhaust extractors.

Now, the solution is going to be adapted for thermal processes, like electric and natural gas furnaces.

Benefits

The model identified a 19% electricity savings potential. The optimisation model first simulated the behaviour alongside the production (digital twin), but now it runs in real time in the BeChained platform workshop to help operators track performance improvements.

Key results

The initial scope of the project was to dig into auxiliary services (i.e. water management, exhaust and dust extraction, air compressing, and more). They are accountable of 20% of electricity consumption.

19% electricity reduction,

$300,000 per year saved from the continuous energy efficiency,

900 tCO2 emissions prevented during 1 year,

ROI: every €1 invested in our solution resulted in €4 saved in the bill,